Ethernet Switches in PROFINET Systems: A Drilling Rig Engineer’s Guide

- Jun 28, 2025

- 5 min read

If you work on a drilling rig, you already know how important reliable communication is for keeping everything running smoothly. Modern rigs rely more and more on industrial networks, and one of the most common standards you’ll come across is PROFINET. But a PROFINET network can only do its job if it’s built on the right hardware — and that’s where Ethernet switches come in.

Ethernet switches are like traffic controllers on your rig’s data network. They make sure that important messages — like those telling your VFD to speed up or slow down — get to the right place at the right time. Picking the right switch, setting it up properly, and knowing what can go wrong are key to keeping your automation systems stable and safe.

In this blog post, we’ll break it all down in simple terms. We’ll look at what makes Ethernet switches different in PROFINET networks, what features you really need, and some practical tips you can use whether you’re installing, upgrading, or troubleshooting switches offshore or onshore. Let’s dive in!

Role of Ethernet Switches in PROFINET Networks

Overview of Network Architecture in PROFINET

PROFINET is built on standard industrial Ethernet, which allows all devices — PLCs, drives, HMIs, and sensors — to communicate over a common network. Unlike older serial networks, PROFINET supports flexible network topologies and high-speed data exchange, making it ideal for automation on rigs and other industrial setups. Ethernet switches sit at the heart of this architecture: they control and direct the data traffic so that each device gets the information it needs without delay.

In short, a switch forwards messages between devices based on their MAC addresses, making sure communication stays efficient and reliable even as you add more devices to the network.

Star, Tree, and Ring Topologies

PROFINET networks can be set up in several topologies, each with its strengths:

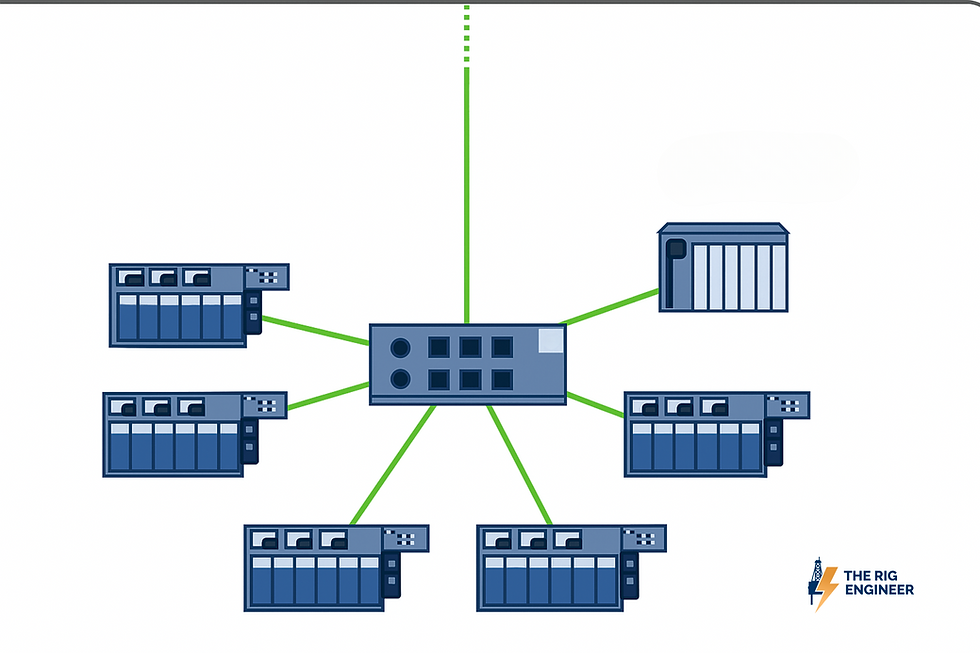

Star topology: In a star setup, every device connects directly to a central switch. This is the most common and easiest to manage. If one device or its cable fails, the other devices continue working normally. However, if the central switch fails, all devices lose communication.

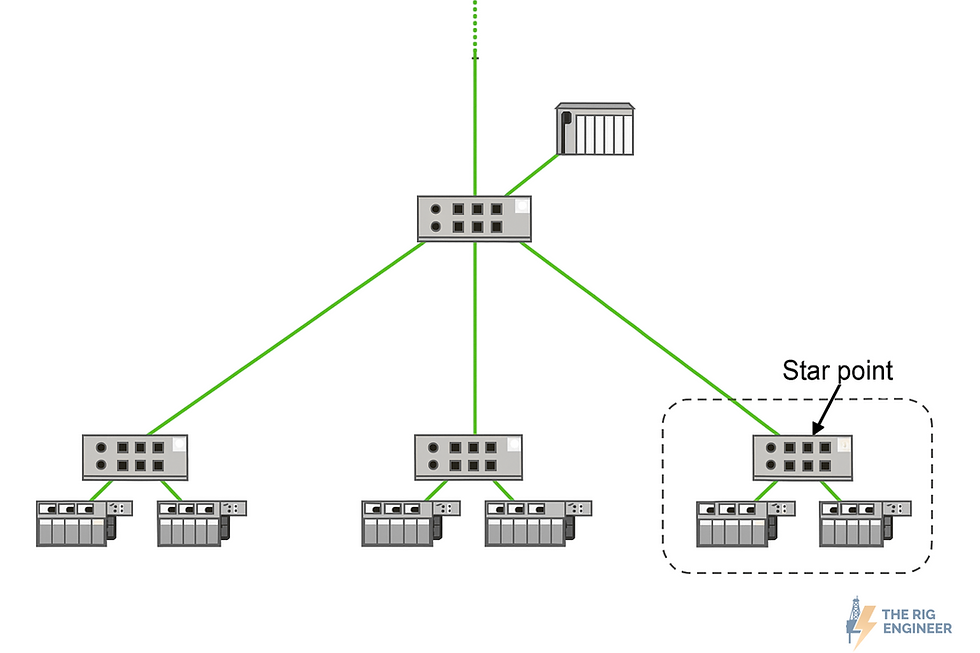

Tree topology: This is like a collection of star networks linked together — one central switch connects to other switches, which then connect to devices. It’s scalable for larger rigs, making it easy to add new sections without reconfiguring the entire network.

Ring topology: In a ring, devices and switches form a closed loop. This setup is popular for PROFINET because of its built-in fault tolerance. If a cable or switch breaks, data can still flow the opposite way around the ring. Redundant ring setups often use the Media Redundancy Protocol (MRP) to recover in milliseconds, ensuring minimal downtime.

Role of Managed vs. Unmanaged Switches

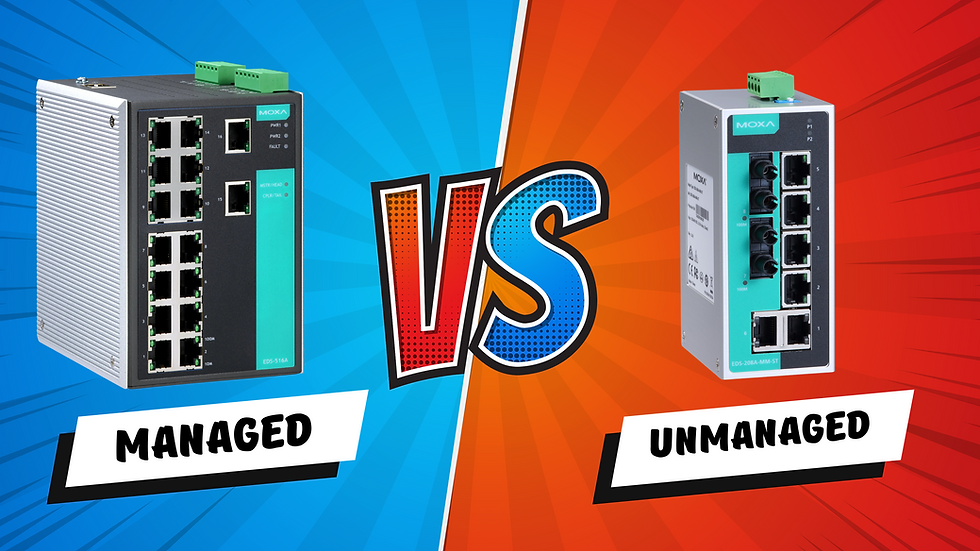

In PROFINET networks — especially on critical systems like those on drilling rigs — you’ll usually want managed switches.

Managed switches give you control and insight. They support advanced features like VLANs, Quality of Service (QoS), ring redundancy, and port monitoring. They can also integrate directly into your PROFINET engineering tools so you can view diagnostics and alarms in the PLC software.

Unmanaged switches are “plug-and-play.” They forward data between devices but don’t give you any visibility or configuration options. They may work for small or non-critical setups but can make troubleshooting a nightmare if something goes wrong, since they don’t offer diagnostics or network status.

PROFINET-Specific Requirements for Switches

Deterministic Communication and Low Jitter

In a PROFINET network, timing is everything. Devices like VFDs, drives, and I/O modules exchange data in fixed cycles — often every few milliseconds — so the switch must forward these messages quickly and predictably. Even a slight delay or variation in delay (called jitter) can cause a device to trip or misbehave. That’s why PROFINET capable switches are built to minimize latency and jitter, ensuring that each message reaches its destination at the right time, cycle after cycle.

Priority Handling and Quality of Service (QoS)

Not all data is equally important. In PROFINET, the real-time control frames need to jump to the front of the line ahead of routine traffic like diagnostics or file transfers. That’s where QoS (Quality of Service) comes in. PROFINET switches look at the priority tag on each packet and use IEEE 802.1p prioritization to make sure critical messages always get forwarded first. This prevents slower, less urgent traffic — like an operator HMI screen refresh — from interfering with the PLCs and drives that keep your process running.

Support for Real-Time Classes (RT vs. IRT)

PROFINET defines different real-time classes to suit different automation needs:

Real-Time (RT) — the most common. RT communications bypasses the usual TCP/IP layers for faster data exchange and is typically sufficient for most automation tasks.

Isochronous Real-Time (IRT) — used for high-speed, time-critical applications like coordinated motion control. IRT requires extra hardware support and precise time synchronization between all devices.

Your switches must support the real-time class your system requires. RT is fine for most rigs, but if you’re dealing with demanding IRT devices, you’ll need specialized switches that can schedule messages and maintain strict timing to keep everything perfectly in sync.

Role of Ethernet Switches in the Rig Network

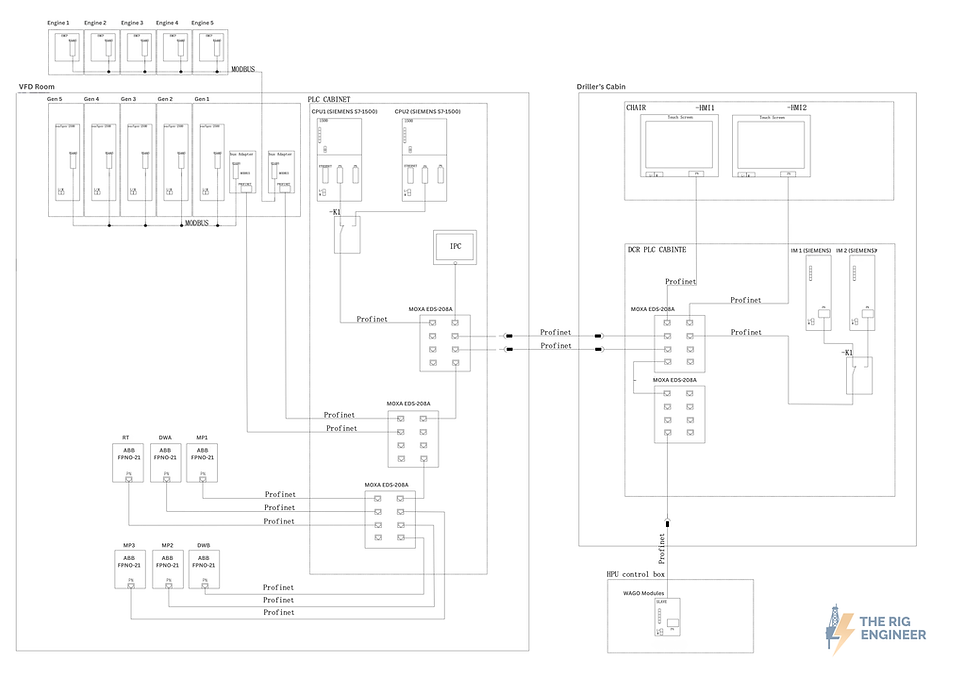

If you look at the rig’s network diagram, you’ll see that Ethernet switches — like the MOXA EDS-208A units — sit at the heart of the entire PROFINET setup. They act like central hubs that keep all the different sections of the rig communicating reliably and quickly.

Here’s what these switches are doing across the rig:

Linking Critical Equipment: The switches connect the two main PLCs in the PLC cabinet to every other device — including VFDs, Profinet modules (ABB FPNO-21), and operator interfaces like HMIs in the driller’s cabin. Without these switches, the data from each drive, sensor, and control panel would have no way to reach the PLC.

Bridging Between Rig Areas: The rig is split into different functional areas, such asVFD room and Driller's Cabin. Ethernet switches bridge these areas together so that data can travel seamlessly between them. Even though these spaces are physically separate, the switches make them one logical PROFINET network.

Handling Multiple Device Connections Efficiently: The diagram shows multiple VFDs, ABB FPNO-21 adapters, Engines, PLCs and operator HMIs all wired into switches. The switches ensure that these devices can send and receive data simultaneously without interfering with each other. Plus, they manage the priority of the messages, so that critical control commands always get through first.

In short, the Ethernet switches in this rig network make all the automation systems talk to each other reliably, help prevent downtime through built-in redundancy, and give you the visibility to troubleshoot problems fast — which is exactly what you need in a tough, high-demand drilling environment.

Conclusion

Ethernet switches may not always be the most visible part of a rig’s automation system, but they’re absolutely essential for keeping your PROFINET network stable and responsive. Whether it’s making sure real-time data gets through on time, allowing devices to talk across different rig areas, or creating a robust ring that keeps the network running even if a link fails — the switches do a lot of heavy lifting behind the scenes.

By selecting the right switches, configuring them properly, and understanding their role in the bigger picture (as shown in the rig’s network diagram), you can help your rig operate more reliably, troubleshoot issues faster, and keep downtime to a minimum. With a strong, well-designed PROFINET network as your foundation, all of your automation — from VFDs and PLCs to HMIs — will have the communication it needs to do its job efficiently.

)%20(1920%20%C3%97%20540%20px).png)

Comments